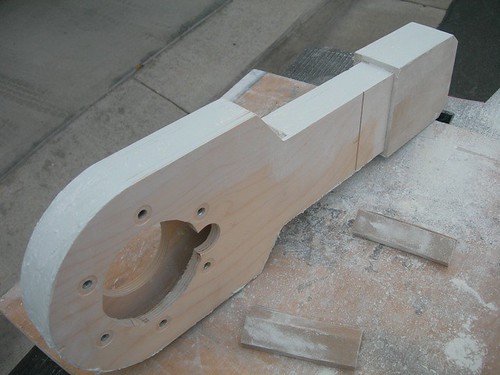

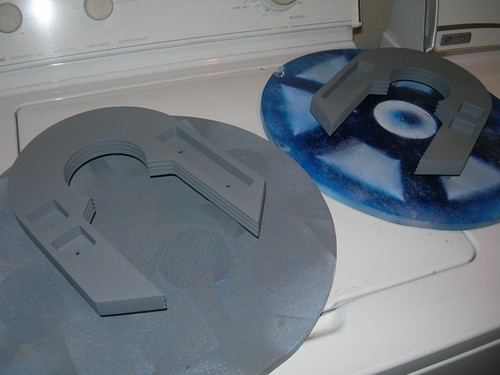

A busy day working on drivetrains with Mike. We had started one drivetrain for one foot last week during the DVD shoot and webcast, and today we started working on the main body pieces for all the other feet.

We are making a total of three droids' worth of drivetrains, two sets for me and one set for Mike. I want two sets because I'm concerned that the Saturn wiper motors on the drivetrain for my completed droid are prone to failure, and these drivetrains will use the NPC 2212 motors, which are much more beefy.

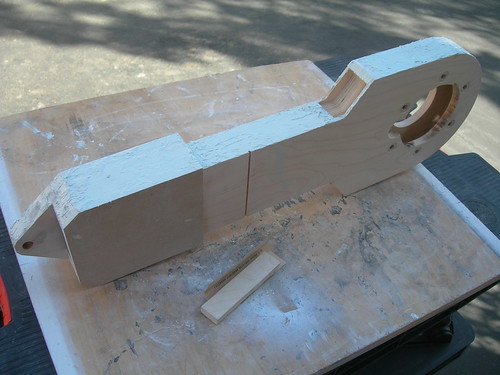

Mike started with the 55 degree cuts on the main body pieces. I'm still amazed that you can chop-saw aluminum.

I got into the act by chopping the corners off some of these pieces, so that they will fit within the foot shells.

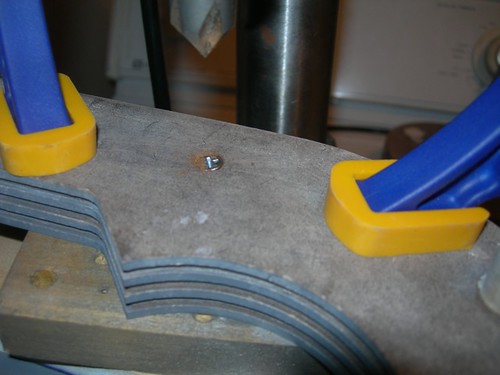

I never miss an opportunity to photograph sparks from the bench grinder! Here, Mike is grinding down the hole saw that we are using to drill the 3/4" diameter holes for the bushings that hold the axles in place.

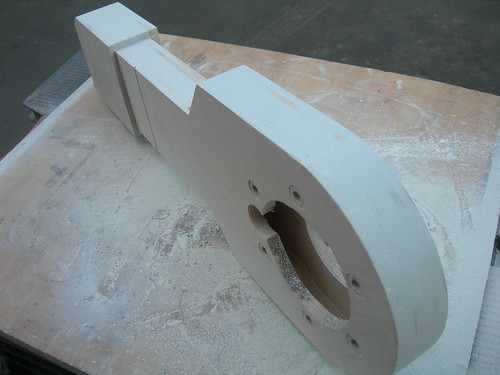

The hole saw needs to cut through one side of the main body, and on through to make a pilot hole on the other side, so that the holes on both sides will be in perfect alignment. Once the tip of the pilot bit cuts through the bottom side, then we can stop the drill press, turn the piece over, and continue drilling the 3/4" hole.

If you miss the target, you get the Spirograph art that Mike created here.

Both Mike and I worked on drilling a lot of these holes.

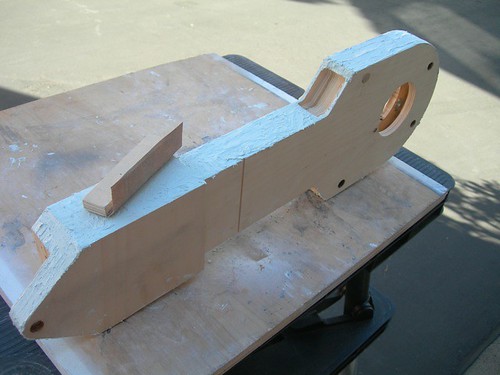

Next, we hopped into the car and drove over to Brian Mix' house, where he graciously let us use his very capable band saw. Mike cut out a portion of the bottom of each main body piece to allow the wheels to fit in.

Not a bad day's work.

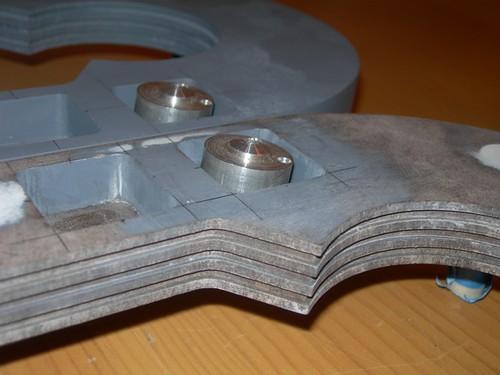

My homework assignment is to cut the key stock and axles to size. The key stock is 1/8" square, and doesn't put up much of a fight against the hacksaw.

In addition to the pieces that Mike already cut for one drivetrain last week, another fifteen pieces of 3/4" length, and ten pieces of 1" length are required. The key stock will fit into the keyways that lock parts such as axels, Delrin rings and gears together.

Ah, cutting through solid steel, how nostalgic. These are the axles that have the keyway already cut into them. These are cut to 4.5" in length.

Mike already cut two of these, I cut three more tonight, with seven more to go. I placed a piece of key stock in the keyway of one of the bottom pieces to give an idea of how it fits into the keyway. Once all the parts come together, it will be clearer how the keyways and key stock lock the parts together.