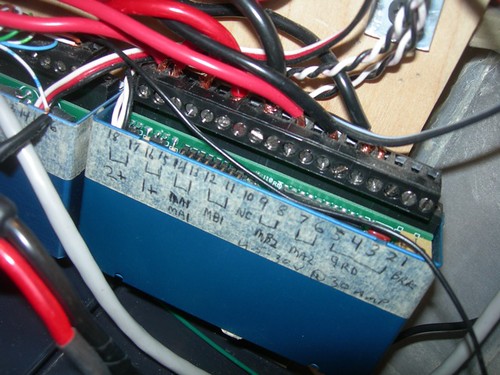

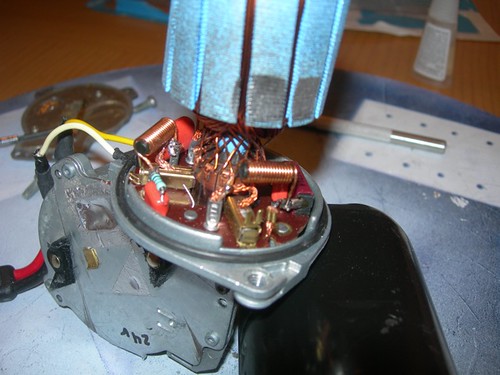

Today I started undoing the 24 volt path in my droid, as I am migrating to a 12 volt system.

The only thing that really makes it 24 volts is the fact that two pairs of 6 volt batteries that are wired in series are themselves wired in series, by connecting the negative pole of one battery bank to the positive pole of the other. Red to black makes this connection.

Unsoldering the wires undoes it.

I now need to connect negative to negative and positive to positive, in order to wire these two 12 volt banks of batteries in parallel. I thought I was going to get to that today, but it didn't happen.

Instead I ran to Orvac Electronics and picked up a 30 amp circuit breaker, to replace the 25 amp circuit breaker I had been using with the Saturn wiper motors. The NPC 2212 motors can draw more current, and I don't want my circuit breaker tripping unnecessarily. I also have the batteries fused for 30 amps, but I'm wondering if this should be increased, to say 35 amps so that the circuit breaker will trip before the fuses blow.

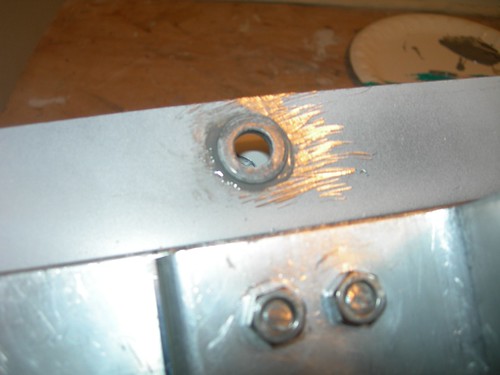

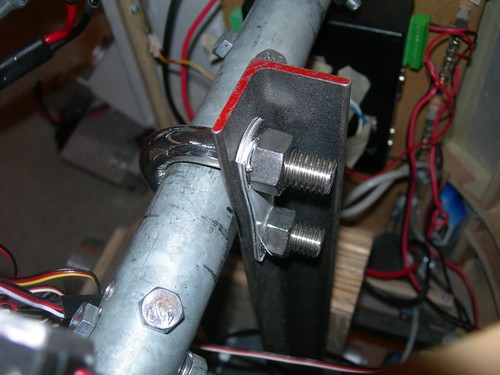

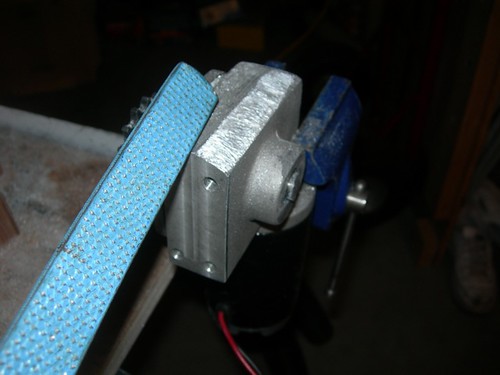

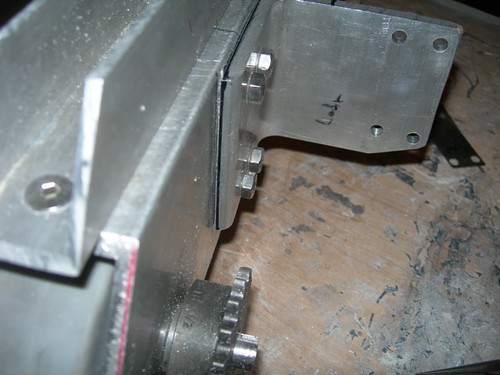

The next item of business was to fix a long standing annoying issue, namely the wiggle room between the gas pipes that connect the legs together.

I clamped some flat boards to the legs to ensure that they were pointing in the same direction, in preparation for drilling more holes for the bolts that lock the gas pipes together.

Then, it was over to the drill press, where I clamped the work down, and even clamped the gas pipe to the drill press, to keep the drill press and gas pipe from vibrating apart from each other.

What were two bolts are now seven! The wiggle seems to be gone, although I won't be positive that this issue is resolved until I get the droid back together again.

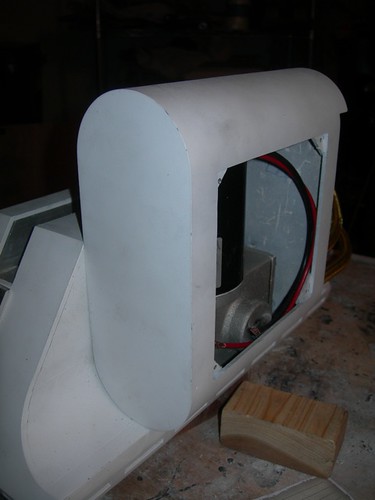

Speaking of which, the poor droid is in an exploded state once again.

I need to file a flat spot on the outer gas pipe to help the angle iron and U-bolt lock in the 36-degree angle of tilt, because Mike reports that the angle of tilt can be altered by the power of the NPC motors. I also need to finish the 12 volt conversion. I hope to make progress on both of those tomorrow.